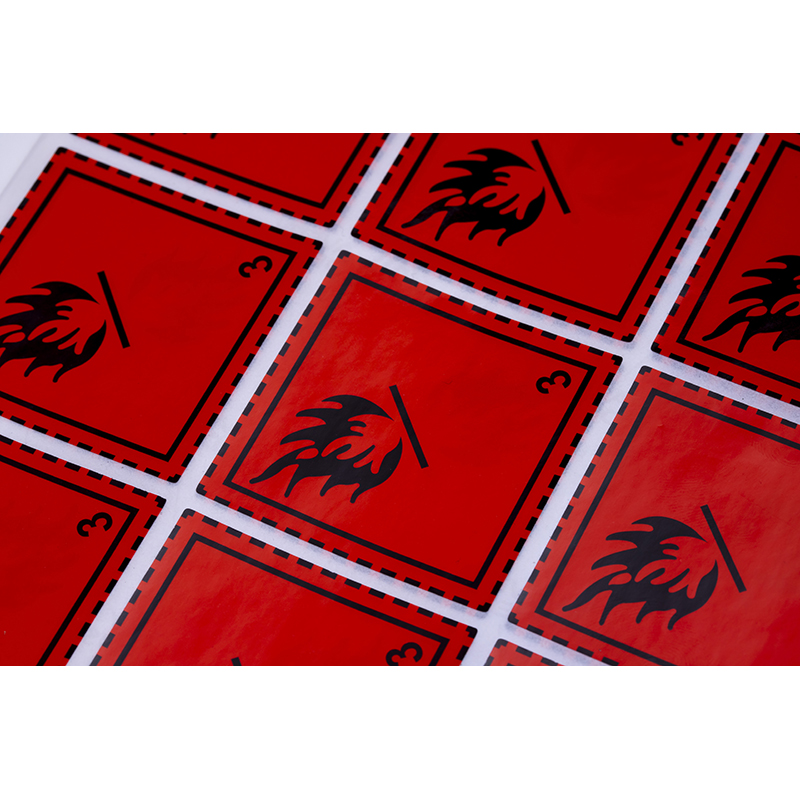

OEM High Quality Custom Label Manufacturers – High-quality Hazardous Chemicals Label – Kunpeng

OEM High Quality Custom Label Manufacturers – High-quality Hazardous Chemicals Label – Kunpeng Detail:

Chemical barrels are used for many products in the chemical industry, such as lubricants, cleaning agents, paints, etc. Common chemical barrels are plastic chemical barrels and metal chemical barrels. The label stickers pasted on chemical barrels are called chemical barrel labels, also known as plastic chemical barrels, plastic chemical barrels, iron barrels and metal chemical barrels. Kunpeng put the chemical barrel on.

The labels used are simply divided into three categories. Class I: plastic chemical barrels. It is a plastic barrel, box, bottle or cylinder made by blow molding or injection molding. The label paper pasted on this kind of plastic chemical barrels usually adopts synthetic paper, which can play a waterproof role. Coated paper is not recommended. Note that if it is a small caliber plastic bottle, the requirements will be higher, because the pasted object is curved and the pasted area is small, which is different from the synthetic paper label used in large plastic barrels.

The second category: metal chemical barrels. For example, oil and industrial paint. Chemical barrels made of this kind of metal are labeled with PP synthetic paper and pet synthetic paper. If there is oil stain on the surface of the chemical barrel, a strong stick oil stain resistant label is required.

The third category: many people think that I want to talk about Glass barrels. In fact, it is not. Chemical products will use small glass bottles, but there is almost no need for large glass bottles and jars, because they are fragile. I want to talk about the third kind of chemical barrels, which are actually chemical barrels with colored GHS compliance labels. It may be made of plastic or metal.

Kippon printed labels are waterproof, wear-resistant, corrosion-resistant and sun resistant. The world’s advanced printing machines and UV inks are used to print outdoor waterproof, scratch resistant, corrosion-resistant and sun resistant self-adhesive labels.

Product detail pictures:

Related Product Guide:

Our workforce through professional training. Skilled professional knowledge, solid sense of service, to fulfill the services demands of consumers for OEM High Quality Custom Label Manufacturers – High-quality Hazardous Chemicals Label – Kunpeng , The product will supply to all over the world, such as: Los Angeles, Ghana, Serbia, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!